Leak Detection and Repair (LDAR) Surveys

Comprehensive Inspection & Monitoring for Emissions Control

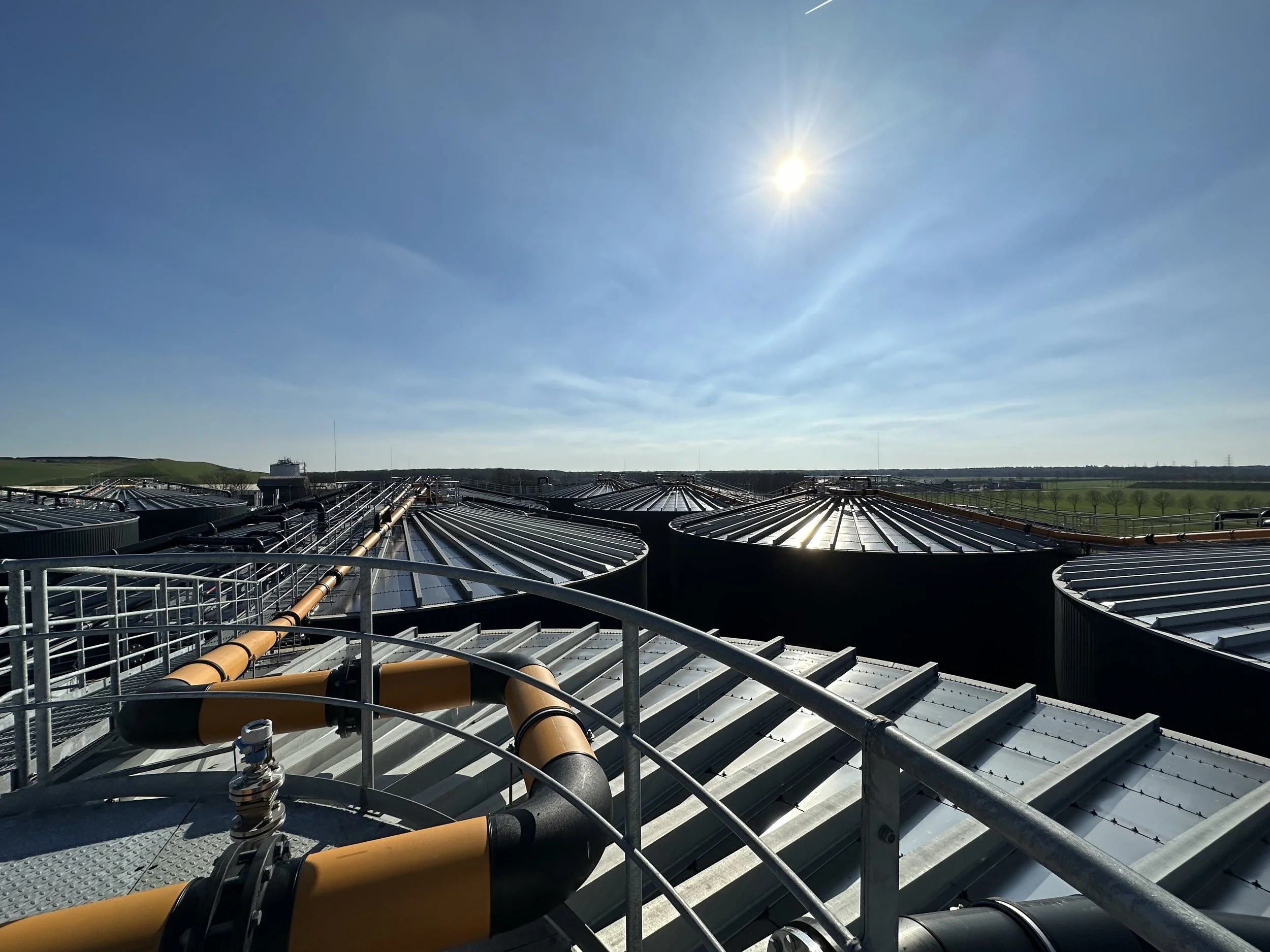

LDAR surveys are essential inspection and monitoring programs used in industries such as oil & gas, petrochemicals, and manufacturing. Their goal is to detect and control fugitive emissions, ensuring safe operations, regulatory compliance, and environmental protection.

What are LDAR Surveys?

LDAR surveys are essential inspection and monitoring programs used in industries such as oil & gas, petrochemicals, and manufacturing. Their goal is to detect and control fugitive emissions, ensuring safe operations, regulatory compliance, and environmental protection.

Identification

Our expert technicians deploy specialized FLIR OGI cameras to detect emissions that are invisible to the human eye.

Classification

Once detected, categorised by size and severity, with each classification guiding the appropriate repair response.

Repair & Follow Up

Compliance & Sustainability

Documentation & Reporting

We maintain detailed records of every leak, including location, severity, and corrective actions. With our FLIR OGI onboard sensors, metadata is automatically encoded into image files—simplifying compliance, traceability, and auditing. Survey results are compiled into reports to satisfy regulatory requirements and demonstrate compliance with emissions standards.

Leaks are repaired promptly, from simple tightening of fittings to full equipment replacements—minimising downtime and emissions. Post-repair inspections can be arranged to confirm that emissions have been fully resolved.

Through LDAR, companies not only comply with environmental regulations but also contribute to cleaner air, reduced emissions, and sustainability goals.

Why LDAR Matters

✔️ Protects the environment

✔️ Ensures regulatory compliance

✔️ Reduces financial losses from wasted product

✔️ Enhances workplace safety

✔️ Strengthens corporate sustainability commitments